Environmental protection on a nano-scale

Even a small amount of oil spilled in a marine environment can have a devastating impact. So small, in fact, that Memorial researchers are working at the nano-level to create sensors for use in harsh environments.

Even a small amount of oil spilled in a marine environment can have a devastating impact. So small, in fact, that Memorial researchers are working at the nano-level to create sensors for use in harsh environments.

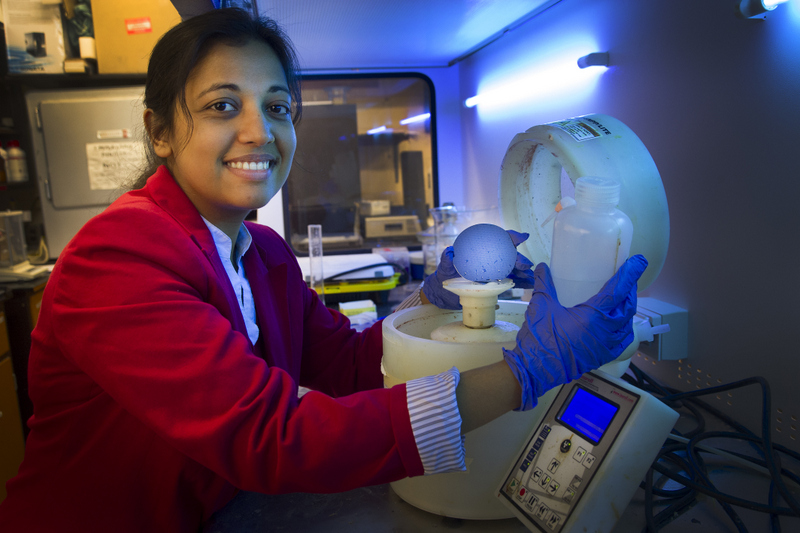

The solid state sensors created by the nanofabricated sensor technology project have little or no moving parts. They can detect contaminants through a specialized material that the molecules land on, sending signals to a reader which would make a spectroscopic measurement and determine what molecules are present based on their particular vibration frequency and volume.

Chief investigators for the project include Drs. Erika Merschrod and Christina Bottaro, Faculty of Science, and Kelly Hawboldt, Faculty of Engineering and Applied Science.

“We are currently designing, developing and inventing new materials to get stronger more specific signals,” said Dr. Merschrod. “We have already created three new classes of materials that promote the binding of molecules and amplification of signals from these sensors, which is really exciting.”

The sensors could function on a buoy or be attached to an AUV during surveys around an oil platform. They could also function on the platform itself, testing water as it comes off a platform and goes back into the ocean, as part of the platform’s own monitoring practices.

“By knowing the details of the chemical composition of that water, not only can we prevent certain molecules from going into the ocean that we don't want there, but oil companies can also make sure their processes are working the way they think they are,” said Dr. Merschrod. “Having something that can give an answer in real time will allow them to respond right away if a module is not working properly.”

The team has primarily been testing the devices in the lab but has recently moved into more realistic tests in the field, attaching them to an autonomous underwater vehicle.

“We did a test in Bonne Bay this past winter and that worked out well,” said Dr. Merschrod. “We haven't tested offshore yet, but we're continuing to develop new materials for use in the real world and we’re also creating a new field of highly qualified personnel, in terms of the students that we’re graduating.”

She says one of the ultimate goals in developing this new technology is to have something that can be manufactured here and sold around the world, stimulating the growth of a new industry in the province. Having graduates trained in these cutting-edge methods would be very important in supporting this new sector.

The researchers have received a grant from the Atlantic Canada Opportunities Agency (ACOA) Atlantic Innovation Fund, with support from Petroleum Research Newfoundland and Labrador (PRNL), the Research & Development Corporation of Newfoundland and Labrador (RDC) and Memorial University. This investment is providing new infrastructure and instrumentation for the university in the form of a nanofabrication clean room, which is currently under construction.

“Being able to make nanostructured materials in an integrated and clean environment is very important, because when you are working on a nanoscale, something as small as a dust particle can be a huge contaminant,” explained Dr. Merschrod.

“A number of us at the university have been working with nano-technology and nano-science and having a clean room where we can integrate the different materials in one setting is certainly going to help us increase capacity for this high-tech research at Memorial.”

Dr. Merschrod believes the industry contacts provided by PRNL will give the team a huge advantage over other companies offering monitoring technologies.

“All of the organizations who are members of PRNL are big multinational companies, and our partnership with PRNL gives us access to direct contacts within this huge market,” she said. “We have a big advantage in being here in Newfoundland and Labrador where a lot of the action is and but the community is still small enough that we can make those connections.”